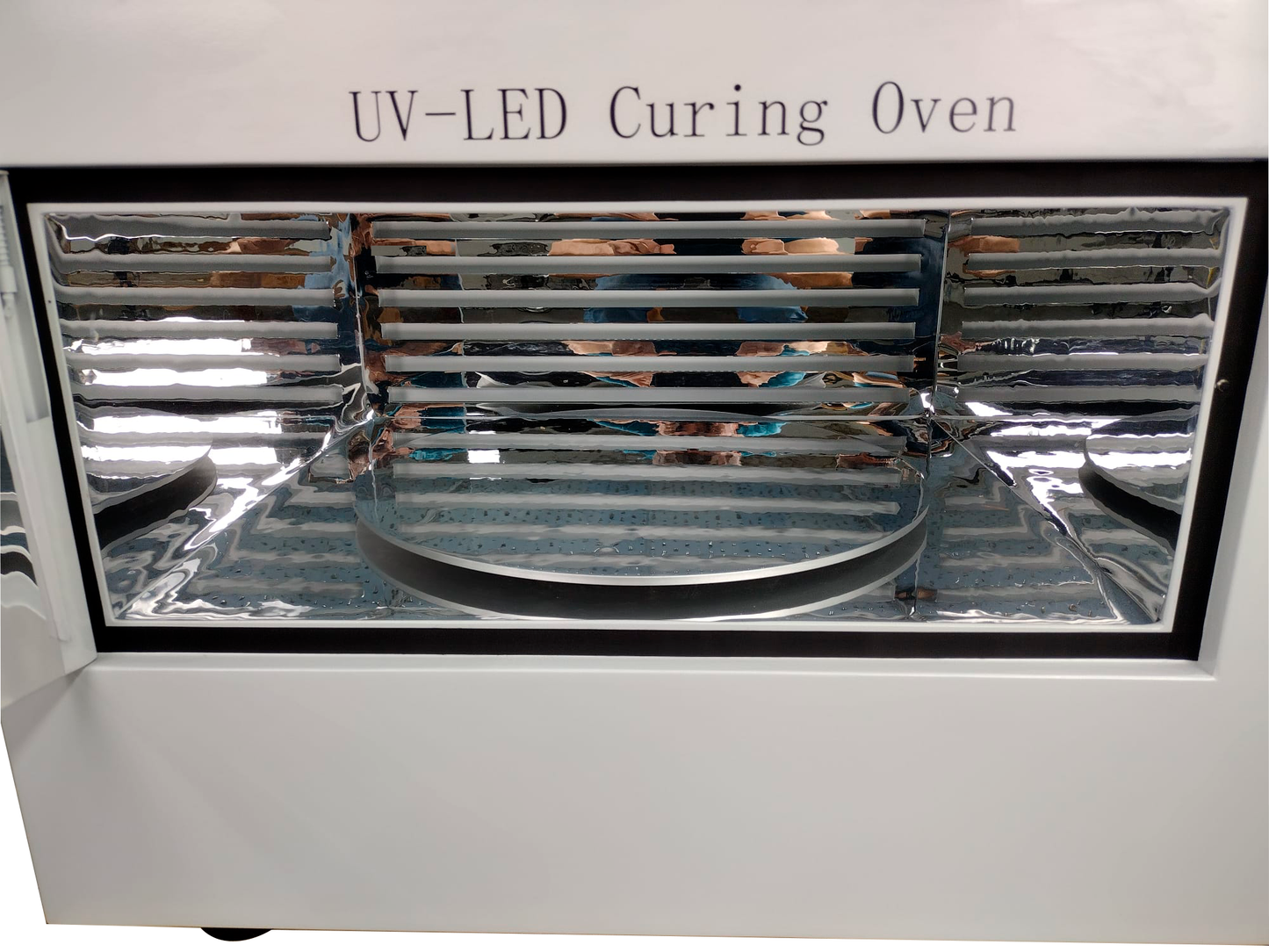

High-Powered LED UV Curing Chamber with Rotating Tray (523mm L x 460mm W x 200mm H)

High-Powered LED UV Curing Chamber with Rotating Tray (523mm L x 460mm W x 200mm H)

SKU:302142-365

Couldn't load pickup availability

The High-Powered LED UV Curing Chamber with Rotating Tray has a curing area of 500x400mm. Wavelengths available in 365nm, 385nm, 395nm and 405nm rapidly and effectively cure most materials, which range from UV glues, inks, and varnishes to paints. This curing system requires no warm-up time and remains cool, protecting heat-sensitive materials and saving you time and money.

The system consists of an oven, UV LED irradiation head, the corresponding connecting wires and a rotary tray that helps light get to every corner of the object or material being cured, making the process more efficient. The irradiation head is comprised of high-quality UV LEDs. The available wavelength for this curing system are 365/385/395/405nm and its effective curing area is 500x400mm. The forced air cooling ensures the system correctly works for prolonged periods of time. Also, this chamber supports external signal input and trigger.

Features:

- Available in 365/385/395/405nm wavelengths are suitable for curing most UV glues, adapting to the job at hand

- Rotary tray helps get more effective results in the same amount of time

- Cold light source makes it suitable for any heat-sensitive material

- Ready for immediate use, maximum light intensity can be reached in an instant

- Easy to control and power saving

- Forced air cooling ensures the system correctly works for prolonged periods

- Mercury-free and ozone-free

- 9.999-second timer

Specifications:

365nm

- Wavelength: 365nm

- Curing area: 500x400mm

- Optic power: 700mW/cm² @ 80mm from LED array.

- Curing cavity size: 523x460x200mm

- Dimensions: 770x502x452mm

- Input Voltage: 220VAC 50Hz/60Hz

385/395/405nm

- Wavelength: 385/395/405nm

- Curing area: 500x400mm

- Optic power: 1000mW/cm²

- Curing cavity size: 523x460x200mm

- Dimensions: 770x502x452mm

- Input Voltage: 220VAC 50Hz/60Hz

User Manual:

Technical Drawing:

Product Video:

If you require higher irradiation, please let us know so that we can offer you our water cooling systems, or if you have questions about this or any of our UV Chambers & Ovens, please feel free to call us at 1(800) 977-7292 or email us at sales@cureuv.com. We would love to help you find the ideal UV solution for your application.